Fuel for Thought

Taking Shape

The chassis has been delivered from the factory to Premier Custom Sleepers in Ft. Worth, TX. Wayne, Brock and the crew get to work. I had the opportunity to visit the shop, and meet Wayne Baylor and Brock Adams, during the build and I was quite impressed not only with the knowledge they have for the work they do but also their attention to detail and flexibility to change.

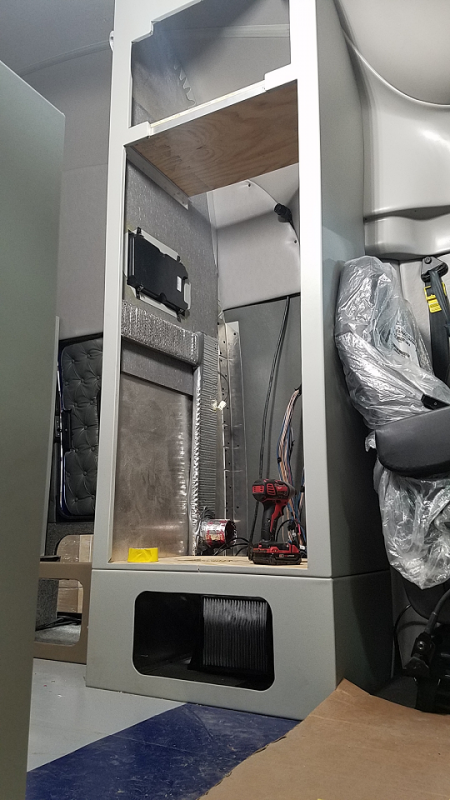

Before they started to upfit my now empty sleeper, we went over the original details. I made a few changes and we got into some very specific details about placement of outlets, floor colors and materials, cabinet colors, shore power outlet location, even down to pre plumbing for the HVAC vents that will later be connected to the APU. Lighting and other electrical needs were determined and Brock’s knowledge in this area was amazing. He walked me through the electrical system, mostly in layman’s terms, and I found out about a lot of the safety features that are included.

If you think a sleeper should be just a box with a bed and a couple of cabinets, you can get a stock sleeper. If you want a few more amenities, a custom option will be a great choice. A lot of planning goes into this custom upfit, and Wayne and Brock oversee the whole process and insist on quality over quantity.

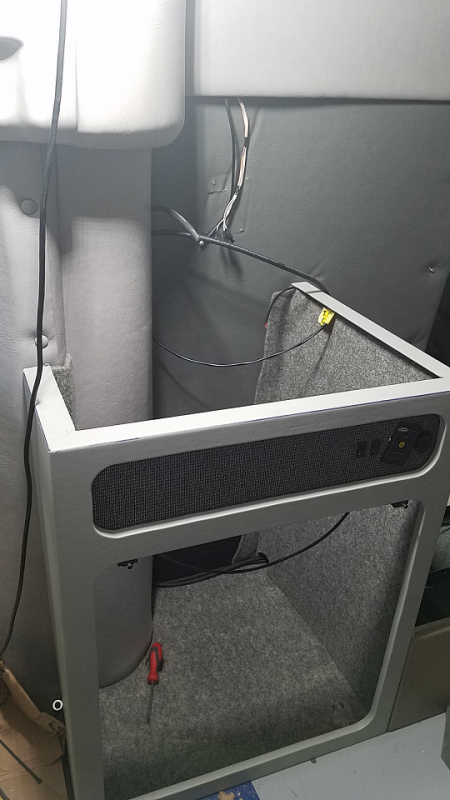

When I visited them, it seemed they were just starting to work on my truck. I say seemed because the truck only had a few components installed. I quickly found out that they had been working much more than I initially saw. As you can see from the photos, it is still pretty empty, but elsewhere in the shop, cabinets were being formed, doors were being made, cushions were being sewn and various other parts were being cut, welded, sanded, finished or covered.

Seeing the lightweight aluminum cabinetry being formed and other aluminum framework being made, you can really see the quality workmanship that goes into each component.

See you down the road,

Greg