I have a question, caused by my own past experience and by watching You-Tube videos of runaway engines.

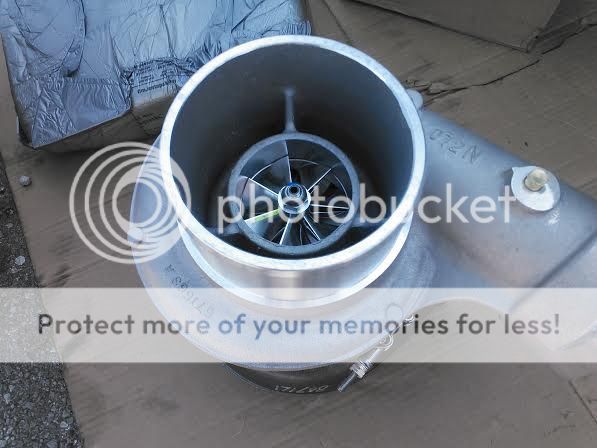

The question is, is there a schedule of any kind for maintenance and/or replacement of the turbocharger? It seems to me this expensive little puppy causes an enormous problem when it fails, so it would be handy to be able to head failure off at the pass, repairing or replacing the turbocharger before it kacks and takes the engine with it--- as seems to happen so often.

While I'm thinking about it, Ford is turbocharging gas engines so they're in this mix too. I don't think a gas engine will run away the way a diesel can, but a blown turbo won't do it any good so a heads-up about when to replace it would be good for them too.

The question is, is there a schedule of any kind for maintenance and/or replacement of the turbocharger? It seems to me this expensive little puppy causes an enormous problem when it fails, so it would be handy to be able to head failure off at the pass, repairing or replacing the turbocharger before it kacks and takes the engine with it--- as seems to happen so often.

While I'm thinking about it, Ford is turbocharging gas engines so they're in this mix too. I don't think a gas engine will run away the way a diesel can, but a blown turbo won't do it any good so a heads-up about when to replace it would be good for them too.