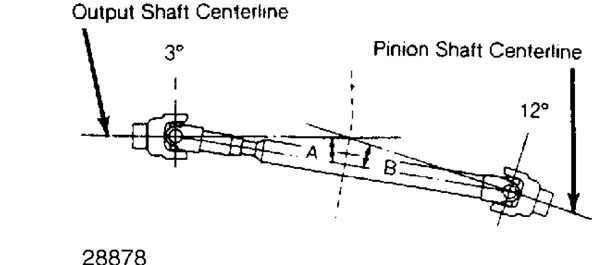

The two shafts don't HAVE to be parallel. That does make it easier. It's also ok if the shafts are completely opposing but otherwise equal. Like this:That is a cool video. So, with a driveshaft you have to make sure that 2 things are correct. The transmission shaft and the rear end shaft must be parallel, and the u-joints must be in phase. Learned something new. Thanks.

You're more likely to see this on a Jeep with a lift kit.

The truck had been towed before, and when the shaft was reinstalled it was done incorrectly. That's why is was out of phase.

Last edited: