Ive got my fingers crossed.Ugh had a short load to Altoona pa today, 30 miles from the delivery going up a hill, the transmission downshifted and boom there went the turbo......

Pulled over to the side of the road and was hoping just a hose popped off but no such luck. Limped the truck to my delivery, when I left there the smoke was really bad, glad it let loose on the exhaust side and not the intake side.

I guess I will find out if that used turbo I bought from eBay is any good, the linkage was frozen, hope that was why it was replaced. Might be the best $200 I ever spent.....

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Big Truck I work on Hino trucks. I'll answer any questions I know the answers to.

- Thread starter greasytshirt

- Start date

-

- Tags

- 2016 hino

- Status

- Not open for further replies.

Ugh had a short load to Altoona pa today, 30 miles from the delivery going up a hill, the transmission downshifted and boom there went the turbo......

Pulled over to the side of the road and was hoping just a hose popped off but no such luck. Limped the truck to my delivery, when I left there the smoke was really bad, glad it let loose on the exhaust side and not the intake side.

I guess I will find out if that used turbo I bought from eBay is any good, the linkage was frozen, hope that was why it was replaced. Might be the best $200 I ever spent.....

If you can get the turbine housing off without destroying many bolts, you will uncover the vanes and cam ring. The ring can get stuck from corrosion or carbon. You can smooth that out with fine grit sandpaper so it moves around easily. Nickel antiseize or molybdenum disulfide paste, or some other ultra high temp lubricant can then be applied to help it stay freed up.

Ive heard of cases ( not with hinos) where people get stuck in the middle of nowhere with a blown turbo. They'd remove the turbo's shaft and wheels completely, then smash shut the oil supply line. Fun times.

If you can get the turbine housing off without destroying many bolts, you will uncover the vanes and cam ring. The ring can get stuck from corrosion or carbon. You can smooth that out with fine grit sandpaper so it moves around easily. Nickel antiseize or molybdenum disulfide paste, or some other ultra high temp lubricant can then be applied to help it stay freed up.

Ive heard of cases ( not with hinos) where people get stuck in the middle of nowhere with a blown turbo. They'd remove the turbo's shaft and wheels completely, then smash shut the oil supply line. Fun times.

I thought about that when I was on my way back home, was wondering how I could have stopped the oil flow to the turbo, didn't think of smashing the feed line.

I had someone go to my place in Florida and find the turbo and send it to me in Ohio, will be here tomorrow, will go back there Friday morning to install the new one. Will try to take few pictures of what happened, pretty sure the exhaust side wheel is in pieces.

You're lucky it didn't dump it in the intake side.I thought about that when I was on my way back home, was wondering how I could have stopped the oil flow to the turbo, didn't think of smashing the feed line.

I had someone go to my place in Florida and find the turbo and send it to me in Ohio, will be here tomorrow, will go back there Friday morning to install the new one. Will try to take few pictures of what happened, pretty sure the exhaust side wheel is in pieces.

The 05-07 trucks will happily run with a worn turbo right up to the point where it grenades.

08 and up tends to have regens affected too much by worn out turbos, so they tend to get replaced before that happens.

Well I got lucky, the turbo was dumping oil into the intake, but I guess because the turbo wasn't actually moving air that the oil didn't ruin the engine. The intake side wheel was shot, the shaft had lots of play in it, doubt that it can be rebuilt.

Figured I would take the hillbilly way of getting the oil out of the intercooler, took the pipe from the intercooler to the intake off and put rags there to catch the oil and let it run. But there was so much oil in there I ended up having to take it off and use some carb cleaner. Left the pipe off again and let it run for a moment to get the carb cleaner out.

But that turbo I bought off eBay for $200 was good so that was money well spent!!!!

But that wasn't the end.......

Got 20 miles away and heard a pop and hiss, thought one of the hoses popped off, no big deal, but it was a tire, a steer tire, ugh!!!!!

My wife was still behind me in the car so I told her I'm not paying for a road service call so I pulled the tire off on the side of the road and went and found a new one. $470 later got back and installed it and was on my way.

What a day!!!!!

Figured I would take the hillbilly way of getting the oil out of the intercooler, took the pipe from the intercooler to the intake off and put rags there to catch the oil and let it run. But there was so much oil in there I ended up having to take it off and use some carb cleaner. Left the pipe off again and let it run for a moment to get the carb cleaner out.

But that turbo I bought off eBay for $200 was good so that was money well spent!!!!

But that wasn't the end.......

Got 20 miles away and heard a pop and hiss, thought one of the hoses popped off, no big deal, but it was a tire, a steer tire, ugh!!!!!

My wife was still behind me in the car so I told her I'm not paying for a road service call so I pulled the tire off on the side of the road and went and found a new one. $470 later got back and installed it and was on my way.

What a day!!!!!

Don_vincentio

Seasoned Expediter

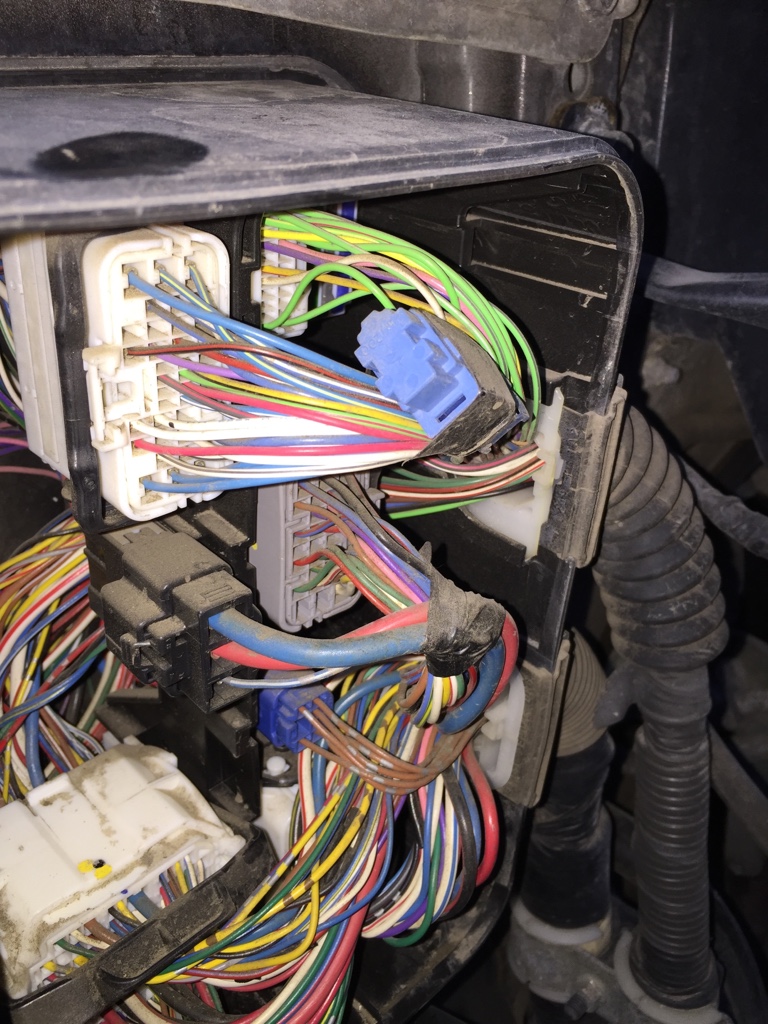

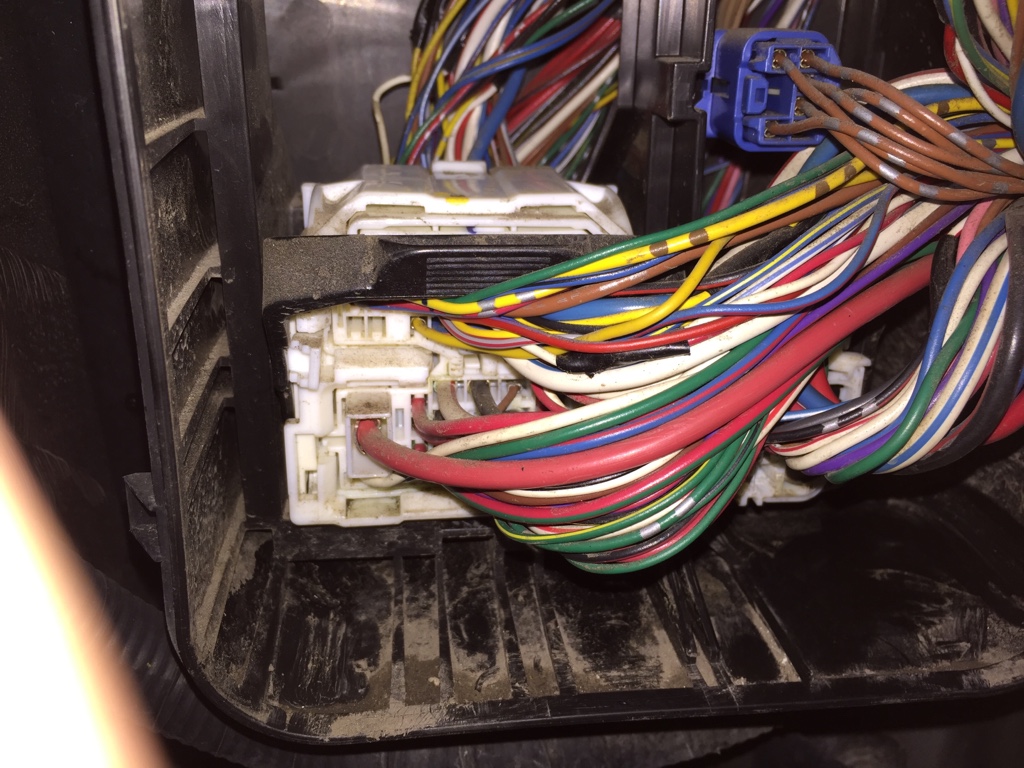

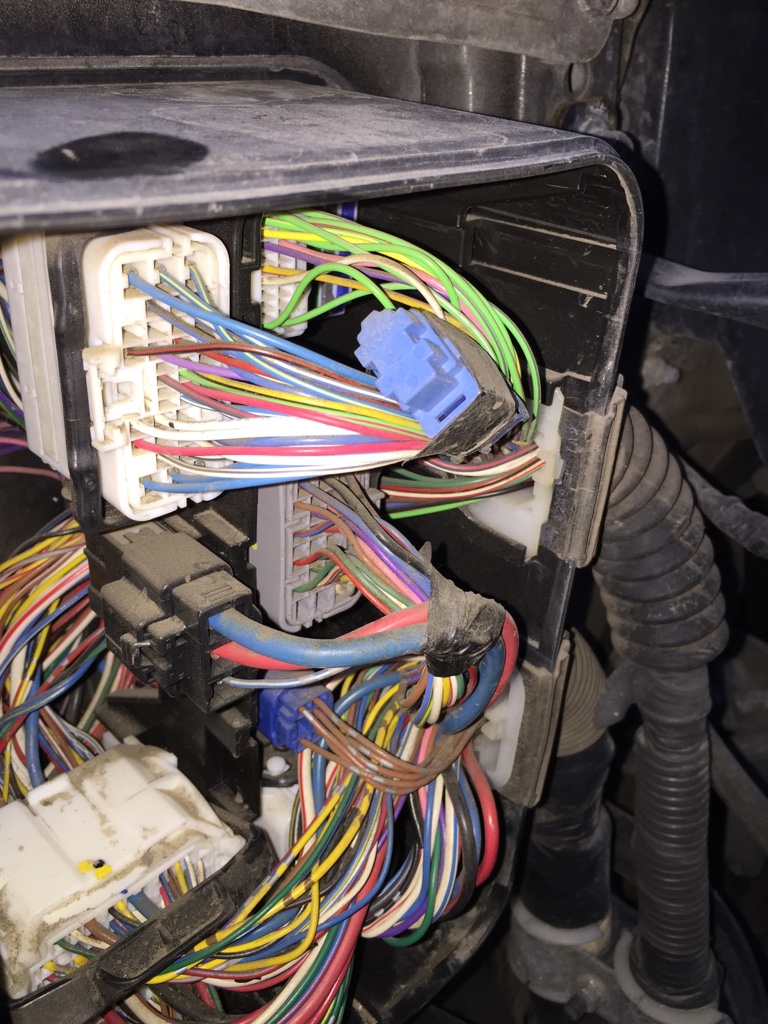

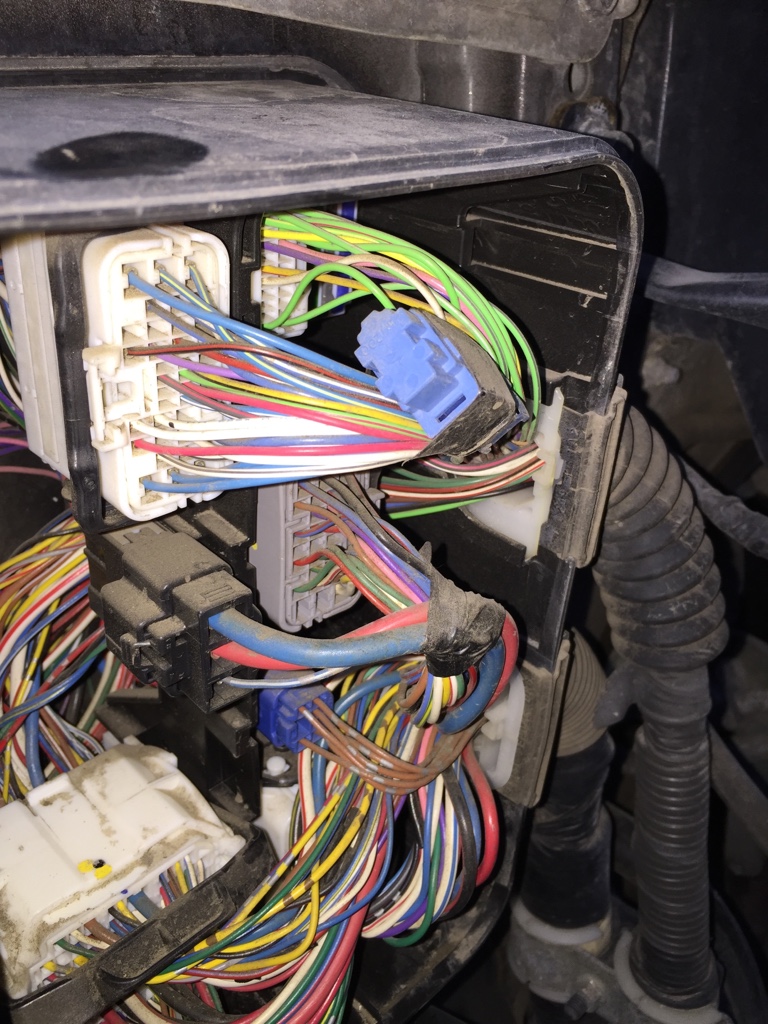

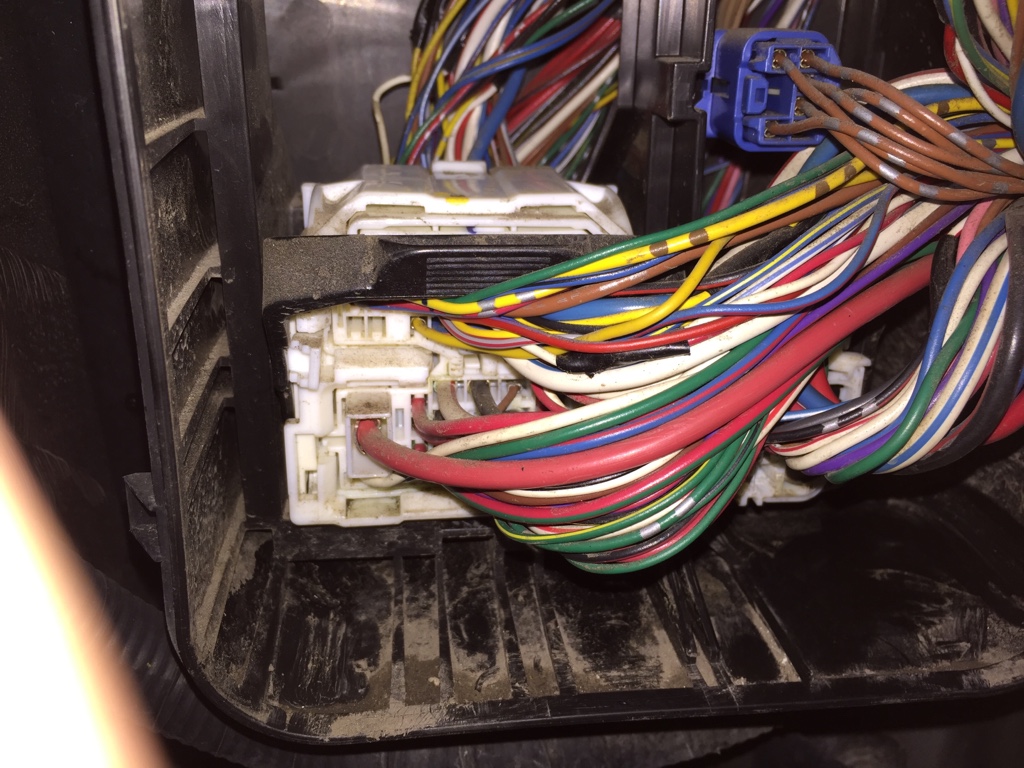

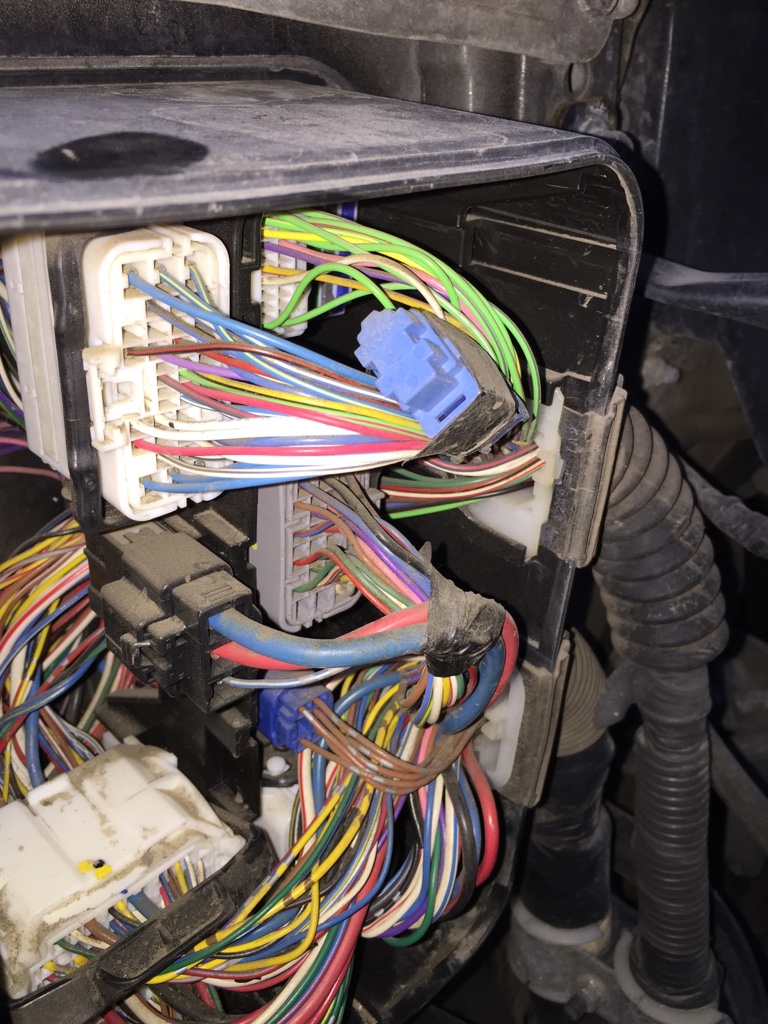

Back to more problems after heavy rainfall, this time though I think I know what the exact culprit is, opened the harness box from under the hood, and there was some residue on the bottom as well as it was wet, and one of the harnesses looks like it's been exposed to water for a while.

Back to more problems after heavy rainfall, this time though I think I know what the exact culprit is, opened the harness box from under the hood, and there was some residue on the bottom as well as it was wet, and one of the harnesses looks like it's been exposed to water for a while.

Last week I ran into a truck with this same issue. And the crazy problems you are describing are not abnormal when water gets in here. Essentially we've run into the solution at about the same time.

This may be warrantable. There is a new cover with an updated seal available. If the pins cannot be cleaned, there is a TSB out on how to replace the harness connectors.

Don_vincentio

Seasoned Expediter

My trucks a 2011 with 163,000 miles what are the chances it's going to be covered under warranty? How do you suggest I bring it up to the dealer? I've got two near me, one that loves to charge for every single thing they do no matter what, and that isn't helpful much, while another may be able to help and might be better with this issue.Last week I ran into a truck with this same issue. And the crazy problems you are describing are not abnormal when water gets in here. Essentially we've run into the solution at about the same time.

This may be warrantable. There is a new cover with an updated seal available. If the pins cannot be cleaned, there is a TSB out on how to replace the harness connectors.

My trucks a 2011 with 163,000 miles what are the chances it's going to be covered under warranty? How do you suggest I bring it up to the dealer? I've got two near me, one that loves to charge for every single thing they do no matter what, and that isn't helpful much, while another may be able to help and might be better with this issue.

Approach them with the knowledge that this is a known manufacturing defect and you want the damage covered under warranty. Ask them to take pics of it and send them to their TSM.

Approach them with the knowledge that this is a known manufacturing defect and you want the damage covered under warranty. Ask them to take pics of it and send them to their TSM.

Please help me greasytshirt I am desperately trying to connect with this 2005 Hino 268 to diagnose a bad vibration I believe is caused by something going on in one of the individual cylinders. Already had injectors replaced along with some connecting rods and pistons about 5 years ago. But she runs rough and shakes pretty badly so I need to narrow it down quickly.

I am trying to connect the Hino diagnostic eXplorer version 3.0 with my Nexiq USB device model 125032 so I can do an injector cut out test to home in on the issue.

However it's not the newer Nexiq bluetooth version, its 125032 as I mentioned which even Nexiq does support anymore. Anyway, when I go into Options-> Communications in eXplorer it only lists Nexiq USB-Link Bluetooth, Hino-Bowe, and 88890020 Adapter as interface options. I've tried each option and variation of settings with no luck, not sure if any of these are compatible with my older USB only Nexiq device.

Problem is I can't get the Nexiq to connect to the truck through any option combo I try in Hino eXplorer.

Interestingly however, when I try the Nexiq Device Tester program it does seem to communicate with the truck on some level as I can see a couple of the "Modules Detected" listed depending what protocol I try with the USB-Link device selected and the second light on the Nexiq turns on.

I've connected the Nexiq to the Hino with the OBD-II and the Deutsch 9 pin connectors and neither seem to work with eXplorer. When I tried to Nexiq Device Tester while connected via OBD-II it wouldn't return any detected modules like while connected with the 9 pin. Although I think I need to have the OBD-II plug to communicate with the engine anyway as the 9 pin only does the tranny etc.

So am I doing something wrong setting up eXplorer using the Nexiq device I have or do I have to get a whole scan tool? If I do have the required equipment then what the hell am I doing wrong?

I go to Equipment DTC and select the catagory, area and equipment then click Load and after loading a few seconds I get a connection error.

Is Hino eXplorer the only way to read and diagnose Hinos or is there a work around using a different method or more general scan tool and or software since I have other scanners etc.

Really would like to avoid spending $1000 on a Hino scan tool, but please let me know what tools I will need anyway just incase!

Thanks a million in advance for any guidance!

Last edited:

It's been close to two years since I've used DX. It's been superseded by DXII. The details are a little fuzzy at this point. Anyway, regular DX will work fine on your truck.

When NEXIQ drivers were already installed on a computer and then DX was loaded, the two wouldn't communicate. Uninstall all of the NEXIQ software. Then go to this page and download the link drivers for your device.

http://www.nexiq.com/support/License_Agreement.asp?fileRequest=USB-Link_Drivers6.0.asp

Do this BEFORE connecting the device to your computer. I seem to remember it telling me exactly when to connect the device. Reboot when you are done and the two should communicate. I'm using the same exact device you are, it functions well with DX. Certainly much better than the old Hino-Bowie, that thing was a piece of crap.

Yes, you need the OBDII connector. The 9-pin works with the Wabco ABS and Allison, no communication with the engine.

PM me your email address.

When NEXIQ drivers were already installed on a computer and then DX was loaded, the two wouldn't communicate. Uninstall all of the NEXIQ software. Then go to this page and download the link drivers for your device.

http://www.nexiq.com/support/License_Agreement.asp?fileRequest=USB-Link_Drivers6.0.asp

Do this BEFORE connecting the device to your computer. I seem to remember it telling me exactly when to connect the device. Reboot when you are done and the two should communicate. I'm using the same exact device you are, it functions well with DX. Certainly much better than the old Hino-Bowie, that thing was a piece of crap.

Yes, you need the OBDII connector. The 9-pin works with the Wabco ABS and Allison, no communication with the engine.

PM me your email address.

I don't know about any other scan tools that work. I imagine something out there will connect, but I'm not sure what.

Bad vibration=dead miss? You might be able to narrow it down with a heat gun on the exhaust manifold.

Is the check engine light on?

If it's a dead miss, and it came on all of a sudden, and there is no CEL (May or may not be lit), then a possibility is a stuck flow damper. There are six of these, they go between the injection lines and the common rail. Now there would be no reason for me to test this with the method I'm about to suggest, but at least one forum member has done this the hard way because he had no way to look at live data. What he did was start the engine and one at a time loosen an injection line at the rail. Beware of high pressure fuel! At idle it's over 7,000psi. Expect the engine to stall. Eventually he got to one where no fuel came out with the line loose. He removed the damper from the rail and disassembled it. He found metal debris inside (presumably from the injection pump) and was able to clean it out and the engine ran normally, at least until it stuck again. Replacing it finally fixed it.

Bad vibration=dead miss? You might be able to narrow it down with a heat gun on the exhaust manifold.

Is the check engine light on?

If it's a dead miss, and it came on all of a sudden, and there is no CEL (May or may not be lit), then a possibility is a stuck flow damper. There are six of these, they go between the injection lines and the common rail. Now there would be no reason for me to test this with the method I'm about to suggest, but at least one forum member has done this the hard way because he had no way to look at live data. What he did was start the engine and one at a time loosen an injection line at the rail. Beware of high pressure fuel! At idle it's over 7,000psi. Expect the engine to stall. Eventually he got to one where no fuel came out with the line loose. He removed the damper from the rail and disassembled it. He found metal debris inside (presumably from the injection pump) and was able to clean it out and the engine ran normally, at least until it stuck again. Replacing it finally fixed it.

A shorted or open circuit injector coil will do this too. Expect a CEL. They will generally ohm out at around 0.7. This is pretty rare. Occasionally the injector harness will break a wire. You can check resistance. Don't handle the insulation on the injector harness, it likes to flake off. That harness is expensive as f#$%. Occasionally one of the little pigtails from the injector to the harness will break a wire inside. You can measure the resistance here too.

I have never seen an ecu failure cause this. Just mentioning this out loud, it seems that a lot of people inexplicably jump to the "The magic silver box is bad!" conclusion for absolutely no reason. I have never replaced a Hino engine ECU.

Off topic: I've seen several Allison TCM's absolutely take a dump though, one destroying the transmission in the process. It seems that the 3000RDS transmission doesn't like having two gears engaged at once at 35 miles per hour. I've never heard such a terrible screech.

I have never seen an ecu failure cause this. Just mentioning this out loud, it seems that a lot of people inexplicably jump to the "The magic silver box is bad!" conclusion for absolutely no reason. I have never replaced a Hino engine ECU.

Off topic: I've seen several Allison TCM's absolutely take a dump though, one destroying the transmission in the process. It seems that the 3000RDS transmission doesn't like having two gears engaged at once at 35 miles per hour. I've never heard such a terrible screech.

A+ Statewide

Seasoned Expediter

Hell if I know, I dont do PM services any more. Just kidding, I'm pretty sure (seriously, if I'm doing a PM it's because everyone at the shop is sick) that they take the same 75w-90 synthetic that goes in the rear axle, but wheel bearings really aren't all that picky. It's in the owner's manual.i have 2014 hino 258alp, recently purchased. what type of front axle oil do i add?

TL; DR: I don't know. I do diagnostic and engine work. I'd look it up but my wife is hogging the desktop.

Edit: is the seal leaking? Be aware that the oil level is between the two lines cast in the plastic. They are not filled to the bottom of the fill plug. If you do have a seal leak, ensure that whoever replaces it adjusts the wheel bearing correctly. This means 0.001-0.003" endplay after the outer locknut is torqued (200 lb/ft is sufficient). Yes, this should be measured (on ANY truck, not just Hinos), but no one ever does. It's the only way to know if it's done correctly.

Last edited:

newage6002@hotmail

New Recruit

can you call me dan at 4044582117 so I can explain what my hino is doing thxHi all. I've been working on Hino trucks almost exclusively for the last few years, and I'm pretty familiar with their ins and outs at this point. If anyone has a question, I'll be happy to answer it, if I know the answer.

Is there a typo in your number? An unenthusiastic lady answeredcan you call me dan at 4044582117 so I can explain what my hino is doing thx

wheelcheck

Active Expediter

Hi all. I've been working on Hino trucks almost exclusively for the last few years, and I'm pretty familiar with their ins and outs at this point. If anyone has a question, I'll be happy to answer it, if I know the answer.

Hey man. Thanks for helping all of us out. I just had a new garbage body installed on a 2006 Hino 268, but I can't seem to get the engine idle to speed up when operating the hydraulics. I took it to the dealer and he programed the computer to rev to 1250 rpm when activated. All the switches are working and it's sending 12v to the red wire with the black tracer behind the dash in the cab, just like all my other trucks, but the engine won't rev up. They only have one guy at the dealer who works on Hinos and he left for vacation this week. Any ideas so I don't have to wait till Monday for him to come back?

Hey man. Thanks for helping all of us out. I just had a new garbage body installed on a 2006 Hino 268, but I can't seem to get the engine idle to speed up when operating the hydraulics. I took it to the dealer and he programed the computer to rev to 1250 rpm when activated. All the switches are working and it's sending 12v to the red wire with the black tracer behind the dash in the cab, just like all my other trucks, but the engine won't rev up. They only have one guy at the dealer who works on Hinos and he left for vacation this week. Any ideas so I don't have to wait till Monday for him to come back?

If the red wire with black tracer has 12v on it, and the ecu parameters are set correctly, it should rev the engine to whatever speed was preset. So either it wasn't set correctly (which is kind of forgivable because the DXII software is not intuitive in it's use AT ALL), or something is taking precedent over the PTO. When setting the pto up like this, the normal fashion is to go into the customization menu in the ECU using DXII and setting the 'preset pto flag' from 0 to 1. Simply clicking on the line and hitting 'ok' doesn't do anything. 'preset pto engine speed #1' value is set to 1250 (or whatever) at the same time. It's easy to eff this up. You can tell I've done it wrong more than once. You won't be able to tell if this is done correctly without DXII.

On your other trucks, is the accelerator pedal disabled, or can you rev the engine with the pto on? Sometimes things are set up like that, and it's possible that the accelerator pedal is damaged showing some throttle application and therefore keeping the pto from activating. Try to pull up on the pedal. I've seen damaged pedals cause regen issues on later trucks since the manual regen process demands the truck stay at an ecu-controlled speed, rather than accelerator pedal selected speed.

Same thing with brakes. The pto setup deal on these is extremely customizable, but very little documentation exists on how to do much other than setting preset speeds. The brake light switches on these things require periodic adjustment and if it's way off it'll cause dumb problems.

Air or juice brakes?

This is hard to answer without being right there with the computer.

- Status

- Not open for further replies.